Material Parameters and Validation for LS-DYNA

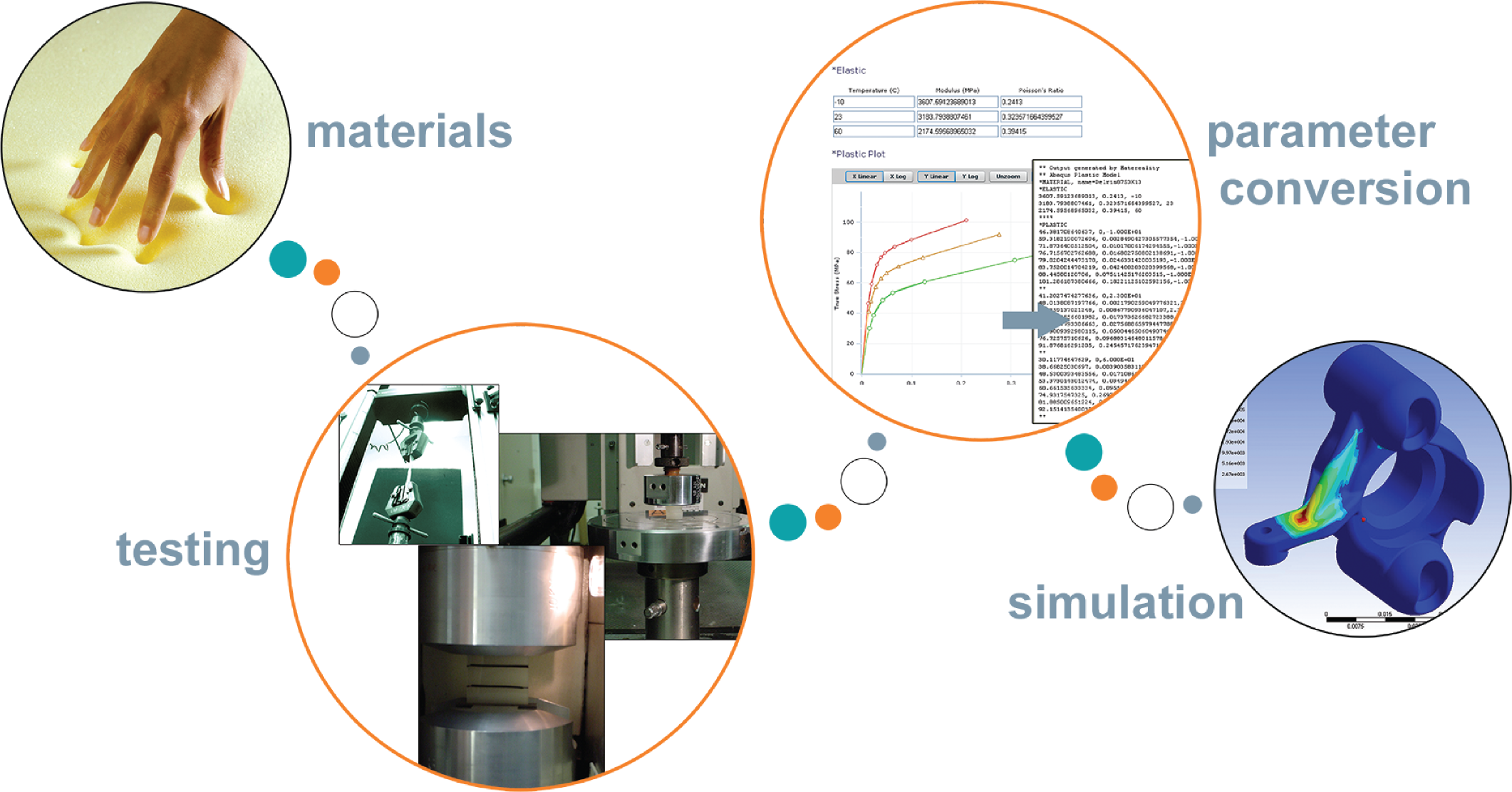

TestPaks are testing suites designed to create CAE-ready material models. Select the right material models, generate the right data, and get it into your simulations, backed up by a team of industry experts every step of the way.

- Contains all the measurements and model fittings needed for your simulation.

- Cost-effective and easy to order - they are available for most common material models.

- Properties are generated the same way, every time for a material model.

- CAE-ready material files are deposited into your CAE Materials library in Matereality.

- TestPaks are available for plastics, metal, foam, rubber, and composites.

DatapointLabs And IDIADA Now Offer TestPaks For GISSMO

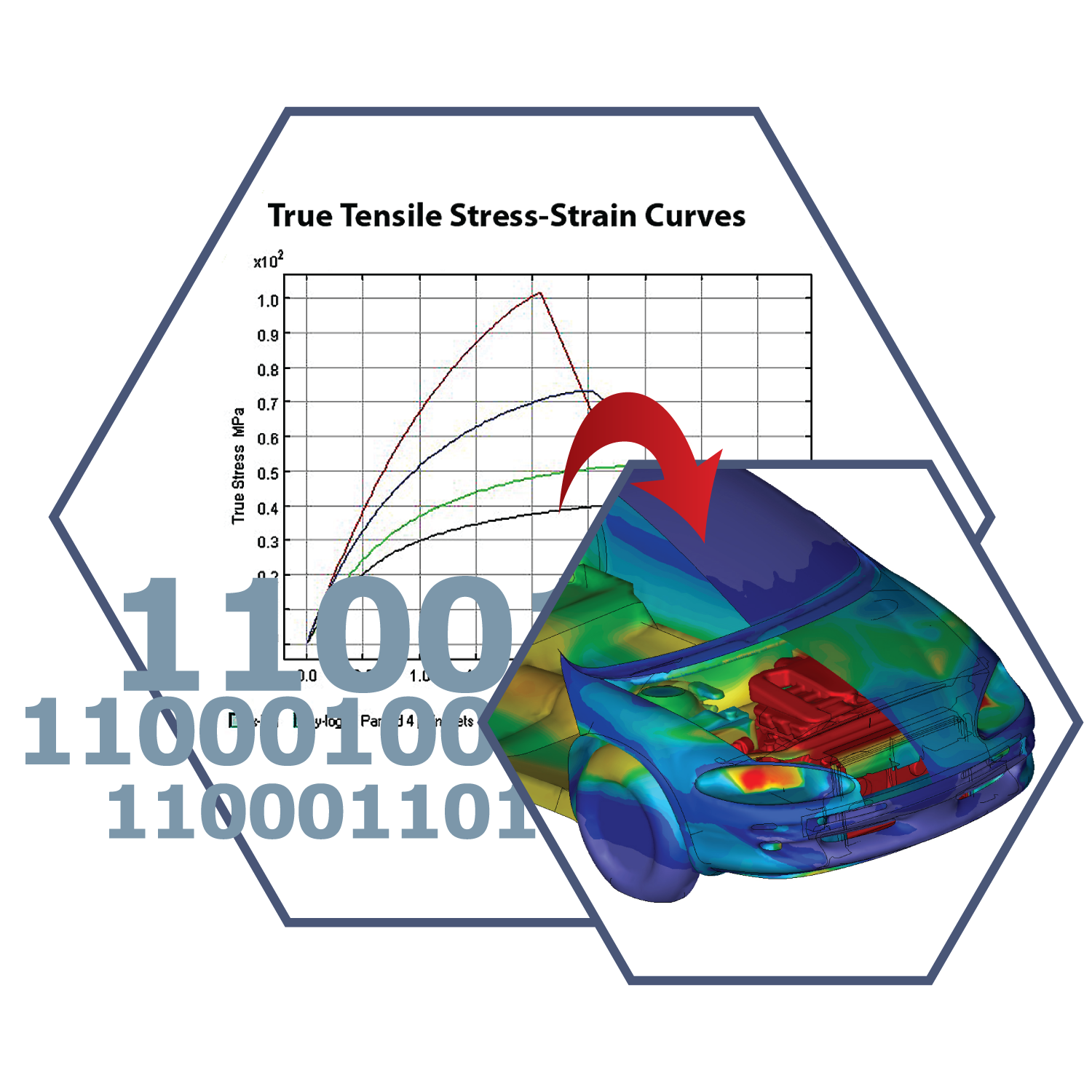

Applus+ DatapointLabs and Applus+ IDIADA have worked together to develop advanced testing protocols and forefront CAE analysis to expand the understanding of material plasticity and fracture, and its consistent virtual implementation approach. Classic plasticity is applied for metals, while advanced pressure sensitive plasticity is utilized for thermoplastics. Material fracture is characterized using the LS-DYNA GISSMO model for reduced and fully integrated shell elements (ELFORM 2 and 16).The main drivers of the material fracture characterization are the accurate measurement in the lab of the actual material behavior, and the generation of the CAE material card, which captures the material plastic and fracture performance, thus ensuring a robust and reliable response when used in automotive full vehicle CAE models. Test data and simulation results are provided to clients on the CAETestBench cloud; this allows clients to use a number of evaluation tools in our software, including curve variability, to examine the variation between test and simulation. IDIADA’s lightweight multi-material body solutions stem from an efficient management of the development tools based on a body design Controlled-Fracture-Driven approach. The aim is to: minimize physical full vehicle prototype phase; inject body lightweight innovation without penalizing development time-frames; and define the foundations of the near future virtual certification applying dynamic building-blocks strategies.

About Applus+ IDIADA

Applus IDIADA is a global partner to the automotive industry with over 30 years' experience supporting its clients in product development activities by providing design, engineering, testing and homologation services. IDIADA's success in product development is built on a unique blend of highly experienced engineers, state-of-the-art test and development facilities and the constant drive towards innovation. The company has more than 2,750 professionals and an international network of subsidiaries and branch offices in 24 countries, ensuring its clients receive customized added-value solutions.

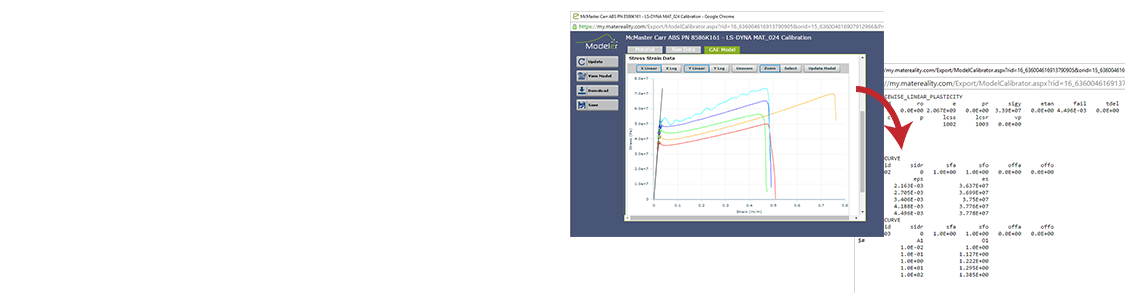

Matereality CAE Modeler

Use our software to convert raw material data into LS-DYNA material cards.

Matereality locates materials in your database which have the property data required by the specified LS‑DYNA material model (MAT_024, MAT_089 or MAT_019), and converts the data into a CAE material file formatted for input to the LS-DYNA solver.

The Modeler creates CAE material parameters from raw material data and writes CAE-ready input material files. This includes simple elastic, elastic-plastic, temperature/ rate-dependent, viscoelastic, hyperelastic material models for FEA, plus injection-molding simulation parameters. A graphical user interface allows for editing and finetuning of the material model parameters prior to material file creation.

TestPaks For LS-DYNA

- G-770 LS-DYNA High Speed 3 Point Flexural Rate Dependent Model (MAT_019 or MAT_024)

- G-771 LS-DYNA High Speed Tensile Rate Dependent Model (MAT_019 or MAT_024)

- G-771V LS-DYNA Validated High Speed Tensile Rate Dependent Model (MAT_019 or MAT_024)

- G-772 LS-DYNA High Speed Foam Model (MAT_083 or MAT_163)

- G-776 LS-DYNA GISSMO Failure Model

- G-778 LS-DYNA SAMP-1 Semi-Analytical Model for Plastic (MAT_187)

- G-780 LS-DYNA Hyperelastic (MAT_027)

- G-782 LS-DYNA Hyperviscoelastic Rubber (MAT_077)

- G-784 LS-DYNA Simplified Rubber with Rate Dependency (MAT_181)

- G-790 LS-DYNA Forming (Barlat 3-parameter model: MAT_036)

- G-791 LS-DYNA Transversely Anisotropic Elastic Plastic (MAT_037)

- G-792 LS-DYNA Isotropic Elastic (MAT_001)

- G-793 LS-DYNA Plastic Kinematic (MAT_003)

- G-794 LS-DYNA Laminated Composite Fabric (MAT_054)

New TestPaks: