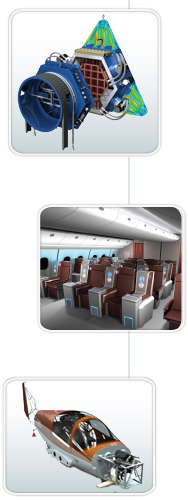

Testing for Aerospace/Defense

The aerospace industry tests for a wide range of properties; while there is some emphasis on certification, a major component is related to new product development. Materials tend to be more exotic and include light weight, high strength plastics that can take high temperatures, crushable foams, and clear plastics that are used in windows and canopies.

High strain-rate testing for use in impact simulations is important. So are thermal properties such as thermal conductivity, diffusivity of insulating materials as well as composites, metals. Flow and thermal properties of fluids are needed for use in design applications. CAE material calibrations for injection molding simulation, structural analysis and impact simulation are commonplace in this industry.

TestPaks typically ordered by this industry

Tests typically ordered by this industry